The increasing demand for top-notch and customized chemicals has led to a rise in the requirement for manufacturing of fine chemicals. Fine chemicals are substances that are produced in small amounts, with specific and accurate specifications for use in various industries such as biotechnology, pharmaceuticals, and electronics. These substances are highly pure and specialized.

This article will delve deeper into the manufacturing of fine chemicals, encompassing its meaning, the process of production, and diverse applications. To learn more about Fine chemicals manufacturing, you can visit our webpage.

What Are Fine Chemicals?

Specialty chemicals, also referred to as fine chemicals, are substances of exceptional purity that are produced in small amounts with exacting standards. These chemicals find use in various industries such as biotechnology, electronics, and pharmaceuticals, where precision and superior quality are of utmost importance.

Fine Chemicals vs. Bulk Chemicals

Large quantities of bulk chemicals, usually measured in metric tons, are manufactured for various applications. On the contrary, fine chemicals are produced in smaller quantities, typically measured in kilograms, and are utilized for specific applications that demand high purity and precise specifications.

Fine Chemicals Manufacturing Process

The manufacturing process for fine chemicals involves several steps, including:

- Synthesis: Various chemical reactions and processes are utilized for the synthesis of fine chemicals, which are subsequently purified to eliminate impurities and contaminants.

- Formulation: After purification, the chemicals are processed to cater to the particular needs of the final application.

Raw Materials Used in Fine Chemicals Manufacturing

Fine chemicals manufacturing employs diverse raw materials that differ based on the intended application. A few examples of raw materials utilized in fine chemicals manufacturing are:

- Solvents

- Catalysts

- Reagents

- Intermediates

Types of Fine Chemicals Manufacturing

Fine chemicals manufacturing can be broadly classified into the following categories:

-

Pharmaceuticals

The pharmaceutical industry extensively utilizes fine chemicals for synthesizing active pharmaceutical ingredients (APIs) as well as intermediates.

-

Agrochemicals

Agrochemicals, such as herbicides, pesticides, and fertilizers, are produced using fine chemicals as well.

-

Flavors and Fragrances

Fine chemicals are also utilized in the production of agrochemicals, including herbicides, pesticides, and fertilizers.

-

Polymers and Resins

The use of fine chemicals is also prevalent in the manufacturing of polymers and resins, which have widespread applications in industries such as automotive, construction, and packaging.

-

Specialty Chemicals

Specialty chemicals such as surfactants, dyes, and pigments are produced using fine chemicals.

Applications of Fine Chemicals

Fine chemicals are used in a wide range of applications, including:

-

Pharmaceuticals

The pharmaceutical industry utilizes fine chemicals for producing APIs and intermediates. Additionally, fine chemicals are employed in drug discovery, development, and delivery systems.

-

Biotechnology

The biotechnology industry utilizes fine chemicals for the manufacturing of biopharmaceuticals, enzymes, and other biologically active substances.

-

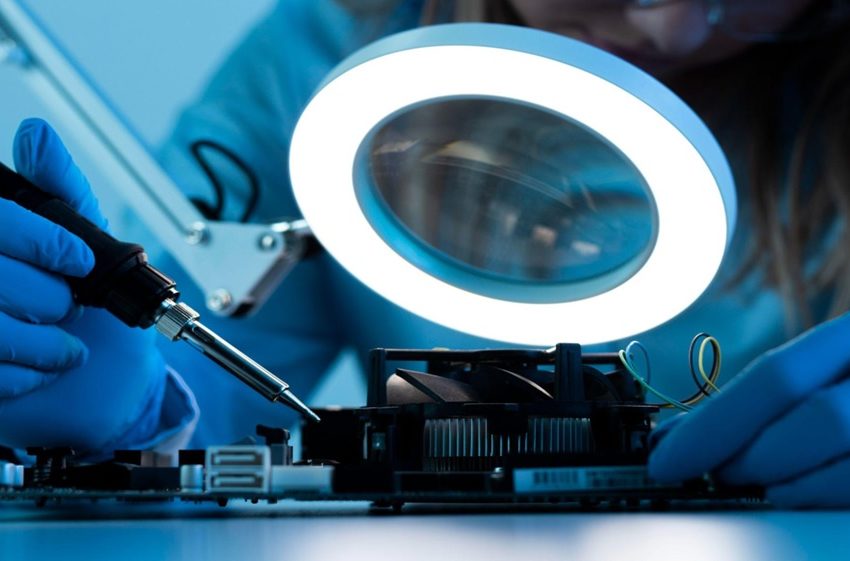

Electronics

The electronics industry utilizes fine chemicals for the manufacturing of semiconductors, displays, and other electronic components.

-

Agriculture

The production of agrochemicals, such as herbicides, pesticides, and fertilizers, involves the utilization of fine chemicals.

-

Others

In addition to their application in various industries, such as cosmetics, food, and textiles, fine chemicals are also utilized.

Benefits of Fine Chemicals Manufacturing

There are several benefits of fine chemicals manufacturing, including:

- High purity: The production of fine chemicals requires a significant level of purity, which is crucial in various fields such as electronics and pharmaceuticals.

- Precise specifications: The production of fine chemicals involves the use of accurate specifications to guarantee that they satisfy the demands of their intended application.

- Customization: Tailored fine chemicals can be produced to suit the precise requirements of the final application.

- Flexibility: The production of fine chemicals is adaptable, enabling the manufacture of small quantities and rapid modifications in the production procedures.

Challenges in Fine Chemicals Manufacturing

Fine chemicals manufacturing also presents several challenges, including:

- Cost: The production of fine chemicals can be expensive because of the need for a high degree of purity and precise specifications.

- Environmental concerns: The manufacturing process of high-quality chemicals may lead to the discharge of dangerous substances and byproducts, causing detrimental effects on the environment.

- Safety concerns: The utilization of harmful and combustible chemicals in the production of fine chemicals can pose a potential danger.

Future of Fine Chemicals Manufacturing

The fine chemicals manufacturing industry is expected to experience growth in the future due to the increasing demand for specialized and high-quality chemicals. Additionally, advancements in technology and innovation, specifically in biotechnology and electronics, are anticipated to contribute to this growth.

Overall, The production of highly pure and specialized substances through fine chemicals manufacturing is essential for various industries such as pharmaceuticals, biotechnology, and electronics. Despite the challenges it poses, the advantages of this process are substantial, and the prospects for the industry are optimistic.