Do you have a new design in mind that can topple your competitors? Have you recently thought of an idea that can improve the branding of your business?

It can be exciting to come up with clever innovations for the betterment of your company, but often, we may find ourselves hindered by limits. Whether it’s the lack of budget or outdated equipment, some of our ideas can fail to materialise.

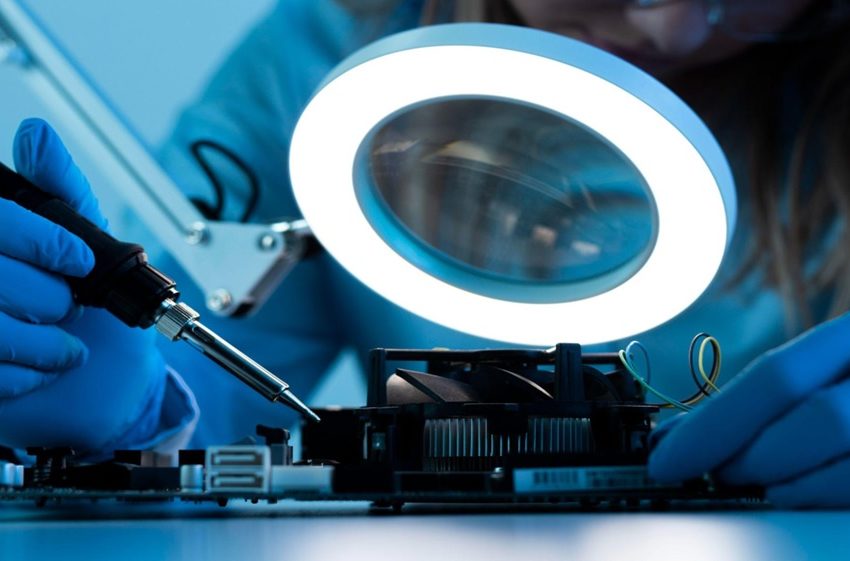

This is where a design, manufacturing, and 3D printing service in Australia steps in.These third-party firms can do everything from laser cut signs in Perth to producing prototypes.

But when is it wise to invest in a design and manufacturing company? Here are (number) signs you should:

- Lack of Expertise

Designing products requires well-developed skills and knowledge, sufficient resources, and a competent in-house team. Not all companies are equipped to handle the responsibility of materialising new concepts, especially small ones.

You can benefit from a third-party firm if your business struggles to understand how to effectively handle a complex design, prototyping, or manufacturing process.

- Limited Resources

As mentioned, it takes plenty of resources to accomplish a design and manufacturing project fully. Unfortunately, small to medium-sized businessesmay not have enough budgetfor additional equipment, design teams, and facilities.

Outsourcing is an attractive solution for developing companies with limited resources. You will only need to pay a certain fee, and the firm will handle everything from design to production.

- New Product Development

Releasing a new product is always a good step towards gaining a competitive advantage. However, the tedious process of introducing products takes copious amounts of time, workforce, and resources.

If you plan to produce a new product, allowing a design and manufacturing firm to assist in creating prototypes and refinement will do wonders. Their guidance and advice can ensure quality before a full-scale production.

- Quality Improvement

Some companies can perform prototyping and manufacturing, but this may come at the cost of quality.

Consider delegating your product innovation to a design and manufacturing team if your products constantly suffer from decreased quality or inconsistent results. They can offer solutions to enhance quality control.

- Demand Variability

Products do not have a consistent demand.

It can be tough to project potential demand for specificitems in your offers, which could result in over or underproduction of inventory.

By partnering with a reliable design and manufacturing firm, you can worry less about producing the correct number of inventory for a certain product. These firms allow you to have a flexible and scalable production.

If your company’s current issues match these listed signs, it is time to seek external help. We highly recommend partnering with Artcom Fabricationto receive an end-to-end solution from design to production.